Nos news

About us title

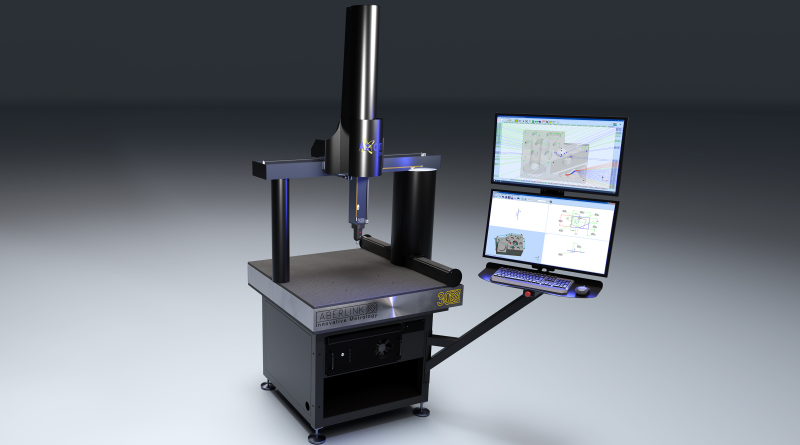

The field of coordinate measuring machines (CMMs) has witnessed little structural concept innovation since its inception, with traditional cartesian configurations such as bridge, gantry, and cantilever designs dominating the landscape. These configurations have served the industry well, offering precision and reliability for decades. However, as the demands of modern manufacturing evolve, so too must the tools that support it. Recognizing this, Aberlink has introduced the EXTOL Delta configuration CMM, a groundbreaking solution that addresses the growing need for cost-effective, space-efficient, and high-performance shop-floor measurement systems.

Understanding the Delta Configuration

At its core, the EXTOL Delta CMM design departs from conventional configurations by utilizing a parallel kinematic structure. This design involves three independent linear actuators working in concert to manipulate the measurement probe with high precision. The result is a compact and versatile machine with a reduced footprint, making it particularly well-suited for shop-floor environments where space is often at a premium.

In recent years the Delta structure has had a significant impact on other areas of advanced manufacturing due to its unique design characteristics and high efficiency with the structures being primarily used in advanced robotics, automated electronics assembly systems and 3D printing offering advantages in precision, speed, and adaptability.

Aberlink’s EXTOL Delta CMM incorporates cutting-edge technology to deliver unparalleled efficiency and accuracy in the field of coordinate metrology. By leveraging advancements in materials, control systems, and advanced software error mapping of the structure by capturing all machine geometry parameters, the Delta configuration achieves exceptional thermal stability, repeatability and accuacy, even in challenging manufacturing conditions. These innovations position it as a disruptive force in the world of metrology. Volumetric measuring accuracy with a Renishaw TP20 touch probe is 2.6 + L/250 µm while with a Renishaw SP25 scanning probe it is 2.3 + L/250 µm.

Benefits of the Delta Configuration

Space Efficiency: Traditional CMM configurations require significant floor space, making them less ideal for manufacturing setups where every square meter counts. The Delta CMM’s compact design minimizes its footprint, enabling manufacturers to integrate precise measurement capabilities directly into production. This proximity to the machining process reduces the time and effort required for part transportation and setup, streamlining workflows and boosting overall efficiency. The EXTOL 520 model offers a XY measuring volume of 520 x 520 mm with a footprint of 950 x 900 mm while the smaller EXTOL 370 offers 370 x 370 mm with an economical 715 x 730 footprint.

Cost-Effectiveness: Manufacturers are under constant pressure to optimize costs without compromising quality. The Delta CMM’s simplified mechanical structure reduces manufacturing and maintenance expenses compared to traditional CMM configurations. Its affordability makes high-quality metrology accessible to a broader range of businesses, including small and medium-sized enterprises that may have previously viewed CMMs as cost-prohibitive.

Robustness in Shop-Floor Environments: One of the significant challenges of deploying CMMs on the shop floor is their susceptibility to environmental factors such as temperature fluctuations, vibrations, and contaminants. The Delta CMM’s design mitigates these issues through enhanced structural rigidity and advanced thermal compensation algorithms. Its ability to maintain accuracy in less-than-ideal conditions makes it a reliable choice for real-time measurement applications in dynamic manufacturing settings. The EXTOL machine mechanical linear bearings and encoder scales, mounted vertically above the measuring volume, are away from potential contamination from dirt and cutting-fluids making the design intrinsically suitable to the shopfloor.

Speed and Agility: The parallel kinematic structure of the Delta CMM allows for faster and more agile movements compared to traditional configurations. This speed translates to quicker measurement cycles, enabling manufacturers to keep pace with high production rates. The Delta’s agility, particularly when utilizing analogue scanning probes, also facilitates the measurement of complex geometries and features, making it a versatile tool for a wide range of applications.

Adresse

Rue Toussaint Gerkens 74, 4052 Chaudfontaine, Liege, Belgium

Liens utiles